Projected Capacitive Touch Panel Product Specification

|

Customer

|

|

|

Production

|

10.1" INCH PROJECTED CAPACITIVE TOUCH PANEL

|

|

Part NO.

|

HX-538GG-0101

|

|

Application Level

|

Sample Used Only.

Mass-Production Used.

|

|

Issue Date

|

2020-06-11

|

|

Version

|

V1.0

|

Please return one copy of this document with your signature for approval.

GENERAL DESCRIPTION

OVERVIEW

This Projected Capacitive Touch Panel can be multi-touch (max to be 10 points touch).

FEATURES

|

ITEM

|

SPECIFICATIONS

|

|

Panel Size

|

10.1 inch

|

|

Structures

|

Glass/Glass

|

|

Total Thickness

|

1.6 ± 0.15 mm (CG 0.7 mm & Sensor0.7 mm)

|

|

Operation Condition

|

-10℃~+60℃ at Min 45% to Max 85% RH

|

|

Storage Condition

|

-20℃~+70℃ at Min 45% to Max 85% RH

|

Note1:In order to make a touch panel operate normally, please make sure that the host device is grounded.

2:

Note2:All environmental characteristics listed as above all should be less than1 atmosphere.

3:

Note3:The touch panel must be assembled with LCD panel by VHB or other materials, the control board also be fixed on LCM bezel or other mechanical parts of the system and then be grounded.

4:

Note4:The touch panel may be damaged functionally or unstable if the panel does not be grounded through your system to earth.

TOUCH PANEL SPECIFICATION

|

ITEM

|

SPECIFICATIONS

|

|

Cover Lens O.D.

|

247.71 mm * 150.28 mm ± 0.2 mm

|

|

Sensor Glass O.D.

|

236.22 mm * 140.68 mm ±0.2 mm

|

|

Cover Lens C/L Visual Area

|

223.72 mm * 126.28 mm ± 0.2 mm

|

|

FPC+PI Thickness

|

0.3 mm ± 0.03 mm

|

Note1:All of the corners and edges of the glass that have chamfer process by CNC machines and all dimensions and tolerances will be defined on the drawing of the touch panel。

RELIABILITY TEST REPORT AND SPECIFICATIONS

MECHANICAL CHARACTERISTICS

|

ITEM

|

CONDITIONS

|

PASS CRITERIA

|

|

Panel

|

Ball Drop Test

|

252g±2g

50cm

|

钢球对准盖板中心自由落体,

3 次不破.

|

|

Hardness

|

Pencil:6H

Pressure:1N/45°

|

Hardness≧6H

|

|

Warpage

|

By Cage

|

Warpage≦Length*0.1%

Unit:mm

|

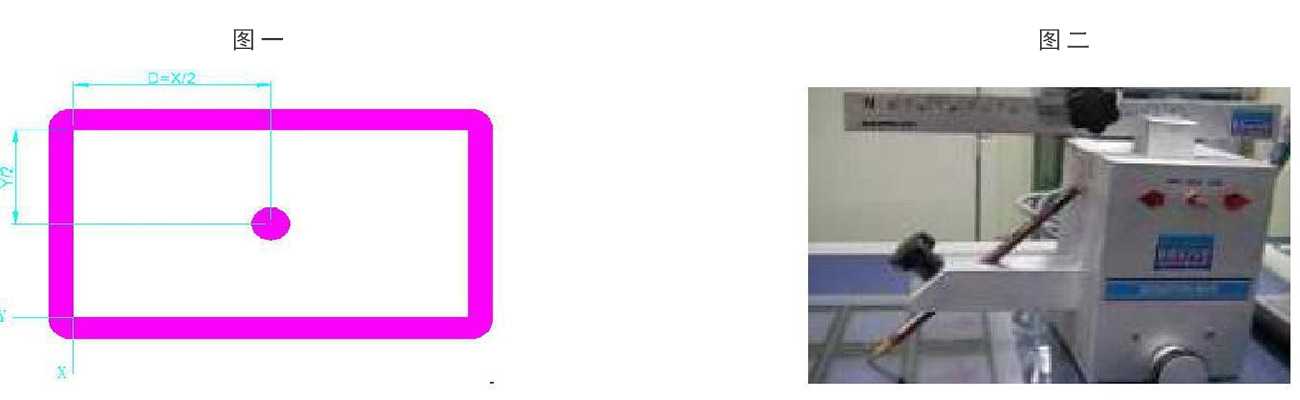

|

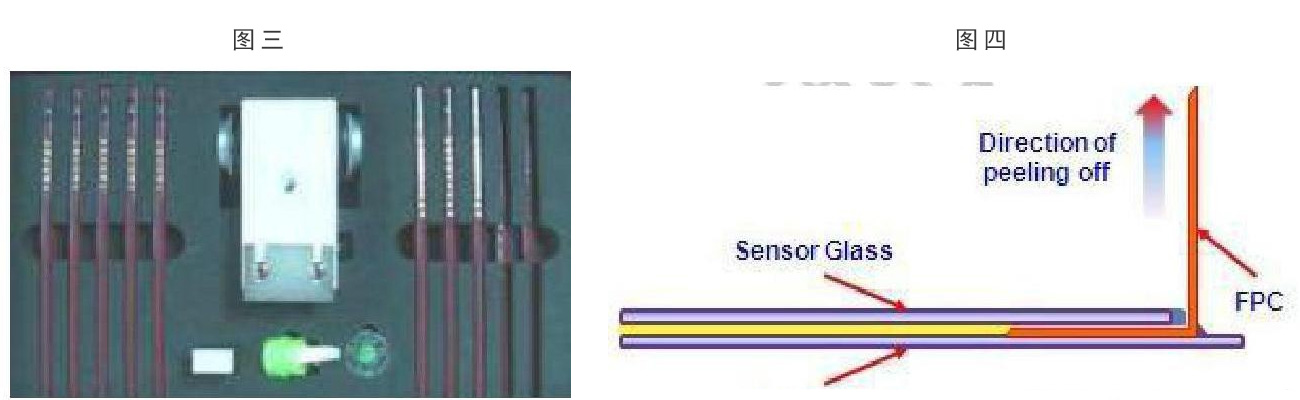

FPC/COF

|

Direction of peeling off

|

90°

|

Strength ≧ 500gf/cm

|

|

FPC/COF Reliability

|

Speed of Pulling out

|

50mm/min

|

.

|

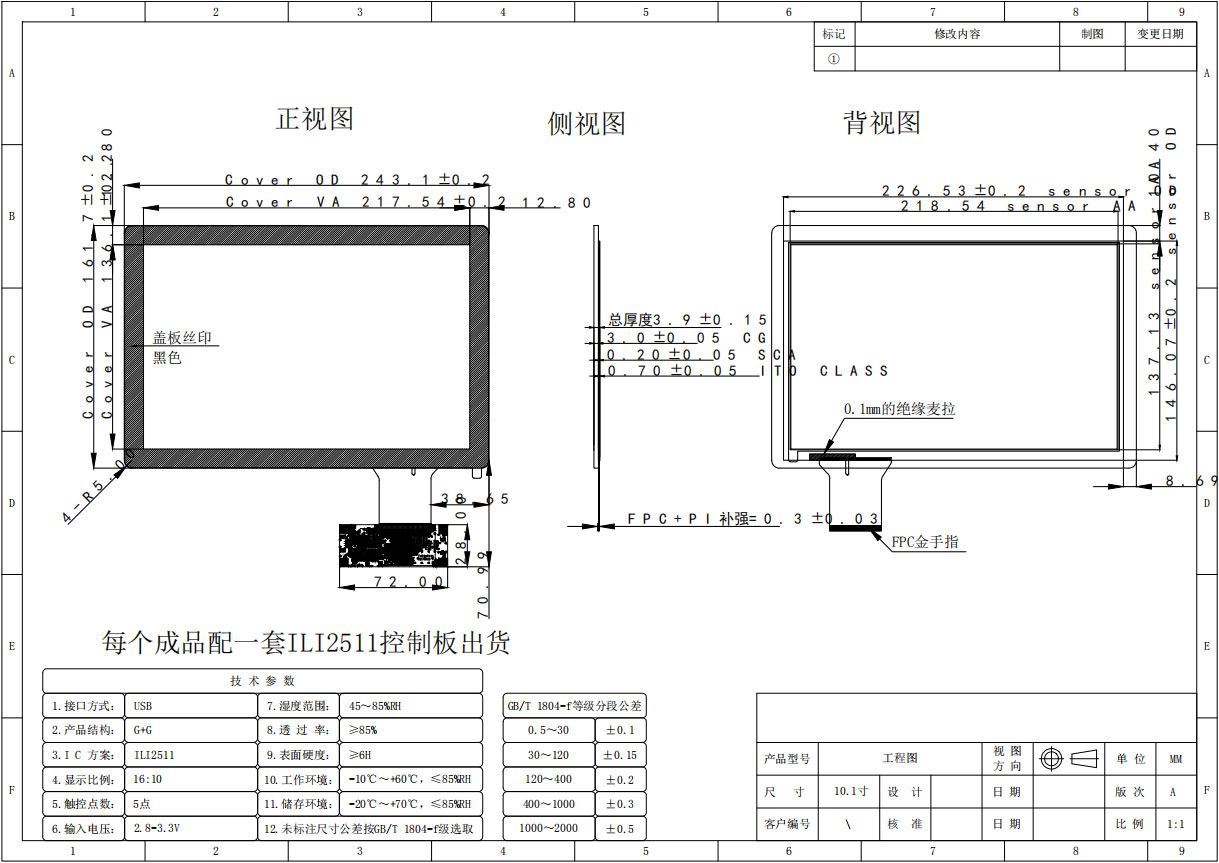

Note1:The ball drop test illustration is showed as follow.

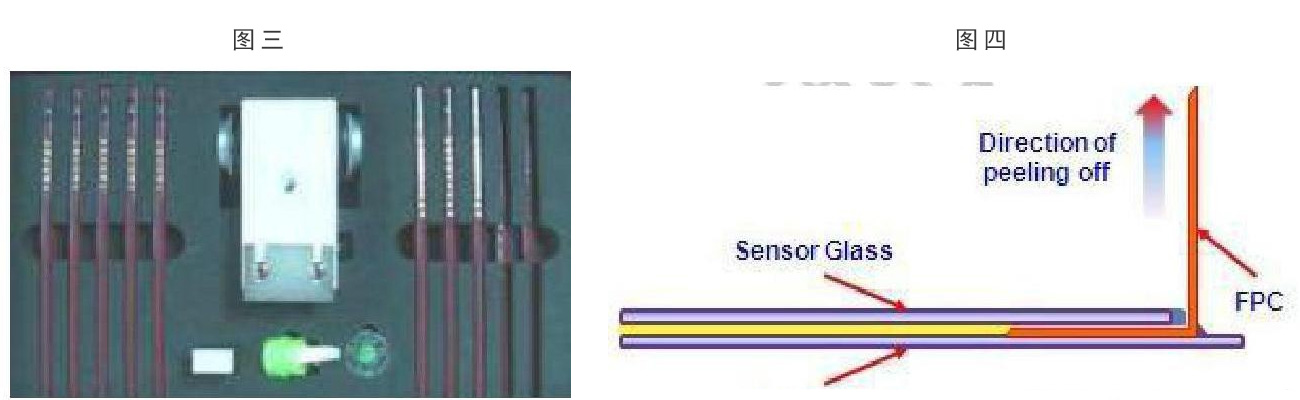

Note2:The hardness test follows up the JIS K-5400 serials industry standard and the test illustration is showed as below.

Note3: The FPC/COF peeling strength test illustration is showed as below, and the test method follows the standard Of ASMT D903/ASMT D3807.

RELIABILITY SPECIFICATIONS

Environment test conditions are listed as follows.

|

ITEM

|

SPECIFICATIONS

|

|

constant temperature and

|

The product should be allowed to stand at 60℃ with 90% RH for 72hrs un-load condition and allowed to be normalized for 12hrs.

|

|

Thermal Shock

|

The product should be allowed to stand at -20℃to+70℃ for 30min/cycle with totally 10cycles and allowed to be normalized for 12hrs。

|

|

High Temp. Storage

|

The sample should be allowed to stand at +70℃ for 120hrs un-load condition and allowed to be normalized for 12hrs.

|

|

High Temp. Storage

|

The sample should be allowed to stand at -20℃ for 120hrs un-load condition

and allowed to be normalized for 12hrs.

|

3. APPEARANCE AND COSMETIC INSPECTION

3.1 Test environment

1. Illumination: 850±150 LUX fluorescent lamp 2. Temperature: 23±2℃ (room temperature)

3. Humidity: 50 ± 10% RH

4. Cleanliness: Class 10000

3.2 Inspection methods and conditions:

1. Conduct the inspection in the specified inspection environment.

2. The eyesight of inspectors should be 0.8 and above for healthy adults. When testing, the eyes should be 30cm away from the TP, and a black cardboard should be placed under the product as a backdrop. The appearance inspection time of each product should not exceed 5 to 10 seconds.

3. Dust-free finger cots must be worn during inspection.

4. Inspection angle of view: reflected light

※COSMETIC DEFECT DEFENITION AND SPECIFICTIONS Product area division:

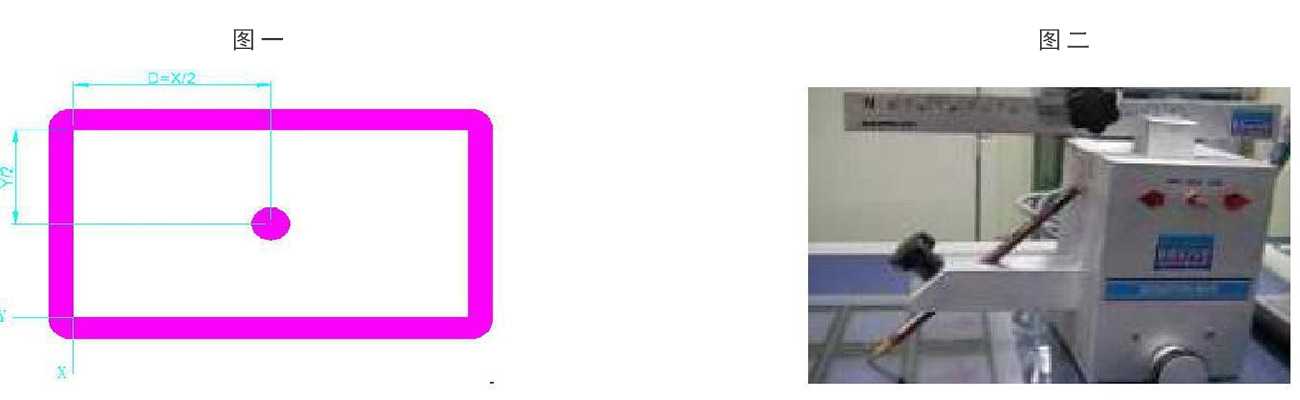

Definition of division of screen A and B area: the length and width of the TP window are divided into quarters on average, and the central four-grid area formed after the division is A area, and the other areas are B area. As shown in the picture:

|

B

|

B

|

B

|

B

|

|

B

|

A

|

A

|

B

|

|

B

|

A

|

A

|

B

|

|

B

|

B

|

B

|

B

|

Product inspection standard:

|

Test items

|

Display area

|

Inspection standards

|

allowable conditions

|

dyslinearity

(scratches/scratches/lines/impurities)

|

A

|

Based on the company's "General Inspection Standard for Capacitive Screens"

|

|

B

|

|

Spotting (bubbles/impurities/white spots/black spots/pits)

|

A

|

|

B

|

|

Chipping/Side

|

Based on the company's "General Inspection Standard for Capacitive Screens"

|

|

Based on the company's "General Inspection Standard for Capacitive Screens"

|

|

(Minor)

|

not allowed

|

|

(FPC)

|

No cracks or breaks

|

Note 1: "L" means length, "W" means width, and "N" means quantity.

Remark 2: The diameter D is expressed as the result of dividing the sum of the lengths of the X-axis and Y-axis by 2; the schematic diagram of the shape of the spot defect is shown in the attached figure. Remark 3: "L" means length, "D" means width; the schematic diagram of the shape of the line defect is shown in the attached figure below.

Remark 4: If there is a dust that is neither dot-shaped nor linear-shaped, please judge and analyze it in the following way; A> Take a piece of transparent and graduated inspection gauge, and place the inspection gauge on the Above the bad object, and first use the point-shaped bad inspection method to judge. B> Assuming that the size of the defective object exceeds the existing point-shaped defect specification in this specification, please change the line-shaped defect specification in this specification for judgment.

Remark 5: Please use inspection gauges as the basis for measuring the size of defective objects.

PRECAUTIONS

|

ITEM

|

EXPLANATION

|

|

Storage

|

A touch panel should be stored under the environment temperature and humidity controlled as suggested.

Do not store a touch panel in direct sunlight.

|

|

Handling

|

Unpack the carton with the printed red arrow pointing up.

|

|

Hold a touch panel body instead of the FPC/COF all the time.

|

|

Avoid that the surface of the sensor glass is polluted after removing the protect film when assembly.

|

Prevent using any kind of the chemical solvent, acidic or alkali solution when cleaning.

Cleaning

Neutral detergent or isopropyl alcohol was suggested if the panel is cleaned.

Do not apply rough force such as bending or twisting to the touch panel during assembly.

Excessive force or strain to the panel or FPC/COF is prohibited. Assembly

Past VHB tape or sponge with adhesive on the gap between a touch panel and a LCD module to segregate water and dust contamination.

|

Operation

|

The panel must be operated in a steady environment, the abrupt change of the environment conditions may cause the malfunction of the panel.

|

|

In order to guarantee all functions of a touch panel stable, please make sure that system is grounded or a power adapter is connected correctly to ground loop (Connection to earth ground is suggested).

|

|

Do not pull the interface connector in or out while the touch panel is operating.

|

|

Any sharp edged or hard objects are interdiction to hitting when touch panel operation.

|

|

Others

|

The product meets the specification requirement of the ROHS standard criteria.

Provide 2 years product guarantee under normal operation Conditions.

If the panel will be used in extreme conditions such as high temperature, high humidity, high altitude or long operation time etc., It is strongly recommended to contact for field application engineer’s advice. Otherwise, Its reliability and function may not be guaranteed.

Avoid high voltage and/or static charge being applied to touch module.

Keep the panel surface clean. Prevent any kind of adhesive applied on the surface.

To avoid the metal or any kind of the electric conduction materials on the touch screen when you are handling.

Any kind of the nonelectric conductor may cause the malfunction when that applied due to touch screen is sensing by human body.

Please finish installation within 30 days after the products. Otherwise, Due to the storage environment and too long time stay, the surface of the product will be misty.

|

Note2:The hardness test follows up the JIS K-5400 serials industry standard and the test illustration is showed as below.

Note2:The hardness test follows up the JIS K-5400 serials industry standard and the test illustration is showed as below.

Note3: The FPC/COF peeling strength test illustration is showed as below, and the test method follows the standard Of ASMT D903/ASMT D3807.

Note3: The FPC/COF peeling strength test illustration is showed as below, and the test method follows the standard Of ASMT D903/ASMT D3807.